Welcome Talk To Us By Whatsapp: +86 150 5425 3293

HORIZON NEW QUARTZ STONE FACTORY: SHANDONG LIYIN

Horizon New Quartz Stone Factory Project Total Investment is 1.64 Billion RMB, With An Initial Investment of 300 Million RMB. It Covers an Area of 103 Acres, with a Construction Area of 37,000 Square Meters. The Main Focus is on the Research, Development, and Manufacturing of High-End Intelligent Equipment for Quartz Stone Slabs and the Production of Quartz Stone Slabs. The Project Adopts a “Construction-Installation-Production” Mode to Achieve Fast Speed, High Efficiency, and Significant Returns. After Reaching Full Production, it is Expected to Generate an Income of 660 Million RMB, a Tax Revenue of 80 Million RMB, and Create 200 New Jobs. The Second Phase of the Project is Planned to Occupy 343 Acres, with a Construction Area of 164,000 Square Meters. After Completion, it is Projected to Achieve Sales Revenue of 2 Billion RMB and a Tax Revenue of 300 Million RMB.

HORIZON NEW FACTORY KEY FEATURES

1. High Technology Equipment

Horizon Independently Developed and Produced Fully Automatic Production Equipment for Artificial Stone Slabs, Reaching International Advanced and Domestic Leading Levels. Currently Holding 13 Invention Patents, 16 Utility Model Patents, and 32 Design Patents, Horizon has been Certified by Authoritative Institutions at Home and Abroad, Filling Industry Gaps.

2. High External Orientation of Products

Relying on Fully Autonomous Production Equipment, Horizon has Transformed Equipment Advantages into Product Advantages, Achieving Rapid, Efficient, and Cost-Effective Production of Quartz Stone Slabs. The Products Are Sold to High-End Markets Both Internationally and Domestically, Exported to 66 Countries Including Europe, America, and Southeast Asia, Annual Export Value Exceeding 1 Billion RMB.

3. Innovative Marketing Model

The Project Pioneers a New Generation of Marketing Models Based on the Quartz Stone Product Platform, Integrating Production, Supply, and Sales. Particularly, the Personalized Customization Segment can Directly Target End Consumers, Significantly Enhancing the Overall Level of the Artificial Quartz Stone Industry and Improving Living Environments in a Profound and Meaningful Way.

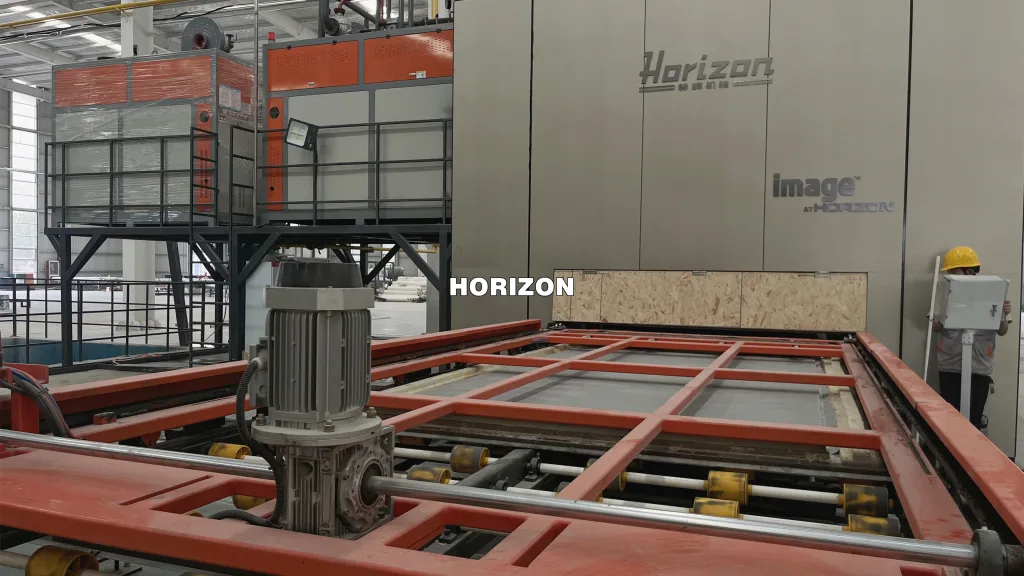

NEW QUARTZ STONE PRODUCTION LINE IN HORIZON NEW FACTORY

Over The Years, Horizon Has Invested Hundreds Of Millions Of RMB In Research And Development Of Quartz Stone Production Equipment. The Unique Mechanical Design And Appearance Design Completely Subvert The Traditional Quartz Stone Industry. At The Same Time, The Production Environment Is Much Better And Modern.

Quartz Stone Production Line Include Two Parts: Press-Curing Line, Polishing Line. Here Is Complete View For You.

PRESS-CURING PRODUCTION LINE

MOST IMPRESSIVE ADVANTAGES OF PRESS-CURING PRODUCTION LINE

1. Lighter, Smaller, More Technological And Efficient

In This Press-Curing Production Line, We Changed The Vertical Mixer And Bulky Spread Equipment, Adopted A Continuous Feeding Spiral Mixing System And A Ferry Spread Machine, Which Not Only Made The Equipment Lighter, Smaller And More Technological, But Also Greatly Improved The Raw Material Mixing Effect.

2. Quality Improve

The Flatness Of Slabs Paving Is Greatly Improved, And The Quality Of The Product Is Also Greatly Improved.

3. Reduce Cost And Manpower

Through Automation Improvements, The Number Of Workers On The Entire Line Has Been Reduced To More Than Half Of That Of A Traditional Line. (In Terms Of The Number Of Workers, The Entire Liyin Press-Curing Line Has 5 People, While Traditional Production Lines Generally Require 9-11 People.)

4. Scientific Structure, Less Space, More Stable

Compared With Similar Products On The Market, Liyin Equipment Has A Better Scientific Structure, Smaller Size, And Better Stability. (Liyin Press-Curing Line Is 50 Meters Long, And 8.2 Meters Wide. Other Similar Equipment Is 103 Meters Long And 11.5 Meters Wide.

5. Energy Saving And Consumption Reduction

Liyin Press-Curing Line Has Also Made Great Improvements In Energy Saving And Consumption Reduction. The Whole Line Power Is About 300KW And Traditional Equipment Is Generally 710KW.

1. MOLD AND PRESS (PRODUCTION LINE 4)

2. RAW MATERIALS DISTRIBUTION ROOM

3. QUARTZ SLAB MOLD

The Raw Materials Stirred By Horizon “520” Mixing Equipment Are Evenly Coated With Colloid, And The Amount Of Resin Is Small.

Calculated Based On A 20cm Thick Slab, The Amount Of Resin Can Be Reduced About 3KG Per Slab On Average. The Spiral Continuous Conveying And Dispersing Method Solves The Shortcomings Of Batch Mixing In Traditional Production Lines, And Continuous Production Also Increases Output. Reducing The Production Costs By 12%.

4. PRESS EQUIPMENT

5. QUARTZ SLAB AFTER PRESS

Through A Series Of Improvements, After Process On Above

- The Pressed Slabs Are Evenly Mixed And Use Less Resin

- The Probability Of Slab Deformation Is Almost Zero

- The Water Absorption Rate Is Less Than 0.05 (The National Standard Is 0.1)

- The Compressive Strength Can Reach 220MPa (The National Standard Is 150MPa)

- The Bending Strength Reaches 35MPa (The National Standard Is 30MPa)

- The High Performance Of Anti-Stain And Anti-Seepage Functions

6. HEAT AND CURING

After Complete The Pressing, The Slab Enters The Curing System.

7. HEAT-CURING EQUIPMENT

IMPRESSIVE HEAT-CURING EQUIPMENT FEATURES

- The Thermostatic Box Adopts A Lifting Type Triple 16-Layer Heating Structure

- The Internal Temperature Of Each Layer Is Uniform

- The Slab Curing Efficiency Is High

- The Flatness Of Cured Slabs Is High

- The Designed Automatic Lifting System Ensures Sufficient Curing Time

- The Circulation Of Slabs In And Out Ensures Uninterrupted Production Through

8. QUARTZ STONE SLAB SEMI-FINISHED

Here Is Quartz Slabs After Heat-Curing.

In Order To Meet The High Quality Standard, The Cured Slab Needs To Be Stored For 1-2 Days Before Entering The Polishing Line.

POLISHING PRODUCTION LINE

MOST IMPRESSIVE ADVANTAGES OF POLISHING PRODUCTION LINE

1. Second-Generation

Liyin Second-Generation Polishing Line Adopts The World’s First Double Five-Head Polishing Structure And Servo Motor Drive System. With Good Performance And First-Class Technological Appearance Design, It Has Become A Top-Notch Products In Whole Industry.

2. Size Available

Four Polishing Lines Can Respectively Meet The Polishing Needs Of Standard Size Slabs (320x160cm) And Super Jumbo Size Slabs (350x200cm).

3. Thoroughly Polish

The Front End Of The Polishing Line Is To Determine The Thickness Of The Front And Back Sides. The Thickness Of The Slab Is Controlled To A Standard Level Through The Tool, And Then The Edges Are Trimmed, Followed By The Fine Polishing Part.

4. Double Five-Head

Compared With Traditional 16-Head And 20-Head Polishing Equipment, The Double Five-Head Design Makes The Mechanical Structure More Stable And More Scientific. The Production Capacity, Slab Flatness, And Brightness Have Also Been Significantly Improved.

5. High Output

At Present, The Production Capacity Of Liyin Polishing Line Can Reach 30 Slabs/H, Compared With 25 Slabs/H For Similar Products. The Average Brightness O Quartz Slab By Liyin Polishing Line Is 50 Degrees, Compared With 40 Degrees For Similar Products, And The Thickness Difference Is Increased By About 20 Filaments.

6. Nano-Coating Technology

The Quartz Slab Surface Through Nano-Coating Technology Greatly Enhances The Gloss, Impermeability, And Anti-Fouling Properties. The Maximum Surface Brightness Of The Slab After Nano-Treatment Can Reach 85-90 Degrees.

9. POLISH EQUIPMENT AND QUARTZ SLAB POLISHING

10. QUARTZ STONE SLABS AFTER POLISH

QUARTZ SLABS FINISH PRODUCT AREA

Quartz Slabs We Produced Include Patterns Ones And Particle Ones. The Pattern Slabs Restore The Texture Of High-End Marble To The Greatest Extent, And The Patterns Are Unique And Beautiful. Its Performance In Bending Resistance, Impact Resistance, Antifouling, And Impermeability Is Much Better Than That Of Natural Stone.

In Addition, We Have Our Own Quartz Stone And Jade Mine. The Mined Ore Is Commonly Known As Agate Stone. It Has Gem-Grade Particles. It Is Unique In The Market And Has Strong Competitiveness.

NEW FACTORY OUTLOOK OF LIYIN

IN THE END

With A New Way Of Doing Business Called The “Quartz Stone Industry Platform,” Horizon New Factory LiYin Project Is Changing How Things Work In The Quartz Stone Industry. This Innovative Approach Is Built On The Foundation Of Making Quartz Stone Production Equipment. With A Strong Supply Chain, Decades Of Experience, High Quality Products, And A Great Team For Both Domestic And Global Trade, We Have Set Up An Efficiency System For Quartz Stone Business, Both Online And Offline. This System Includes Getting The Materials, Making The Equipment, Managing Production, And Handling Orders.

Horizon Is Not Just Making Equipment And Manufacturing Quartz Stone. Moreover, We Are Bringing Every Quartz Stone Businessman Involved Together. This Helps All The People In This Industry Work And Grow Together Better, Connecting The Whole Quartz Stone Industry.

CONTACT US AT

Email: hero@horizon-quartz.com

WhatsApp: +86 150 5425 3293

USEFULL LINKS

HORIZON YOUTUBE CHENNEL: HORIZON GROUP – Top Quartz Stone Slabs Manufacturer

QUARTZ CALACATTA GALLERY: Horizon Quartz Calacatta

HORIZON BEST: Horizon Best Angle

vNWMoYFRlgyGfXhk

pmbSUvfsztaCc

nUPdLShxEXjtk

jkWfEiMNTsUZJ

ekbznGFD

dosyrUFW

rRJQLpcV