Welcome Talk To Us By Whatsapp: +86 150 5425 3293

Horizon Quartz Stone 520 Automated Production Line

Horizon quartz stone automated production line is designed, and produced by Horizon Machinery Department, it combines mechanical equipment, control systems, and information technology to automate the production process. This automated production line can greatly reduce manual operations, improve production efficiency, ensure product quality consistency, and reduce production costs.

Advantage Of 520 Automated Production Line

Improve Production Efficiency:

Automated production lines can perform production tasks continuously and quickly, reducing manual operation time and errors, thereby significantly improving production efficiency.

Reduce Labor Costs:

By reducing reliance on manual operations, companies can reduce labor costs and free workers from heavy manual labor to focus on higher-value work.

Improve Product Quality:

Automated equipment can precisely control the production process and reduce variability in human operations, thereby improving product consistency and quality.

Flexibility And Scalability:

Modern automated production lines usually have high flexibility and can be adjusted and improved according to different production needs, adapting to small batch and multi-variety production modes.

Reduce Material Waste:

By precisely controlling the production process, automated production lines can optimize resource utilization, reduce material waste, and improve production efficiency.

The following are the key components of Horizon 520 automated production line and its advantages:

Components Of 520 Automated Production Line

Mechanical Equipment:

Includes various automated machines, such as robots, conveyor belts, automated assembly equipment, etc., which are used to perform specific operations in the production process, such as material handling, assembly, welding, testing, etc.

Control System:

Use control systems such as PLC (Programmable Logic Controller) and DCS (Distributed Control System) to control and coordinate the equipment in the production line to ensure the smooth progress of the production process.

Sensors And Testing Equipment:

Used to monitor key parameters in the production process in real-time, such as temperature, pressure, position, speed, etc., and feed data back to the control system for adjustment and optimization.

Information Management System:

Includes MES (Manufacturing Execution System), ERP (Enterprise Resource Planning), etc., which are used to manage and optimize production plans, material flow, quality control and equipment maintenance.

520 Automated Production Line Manufactured Calacatta

Traditional calacatta production needs to be produced manually, which is costly and inefficient. As the technology of Horizon automated production of calacatta becomes more and more mature, the cost will drop significantly, and the price will also drop. This will give us a greater advantage in the industry, widen the gap with other companies, and make our position as the industry leader more stable.

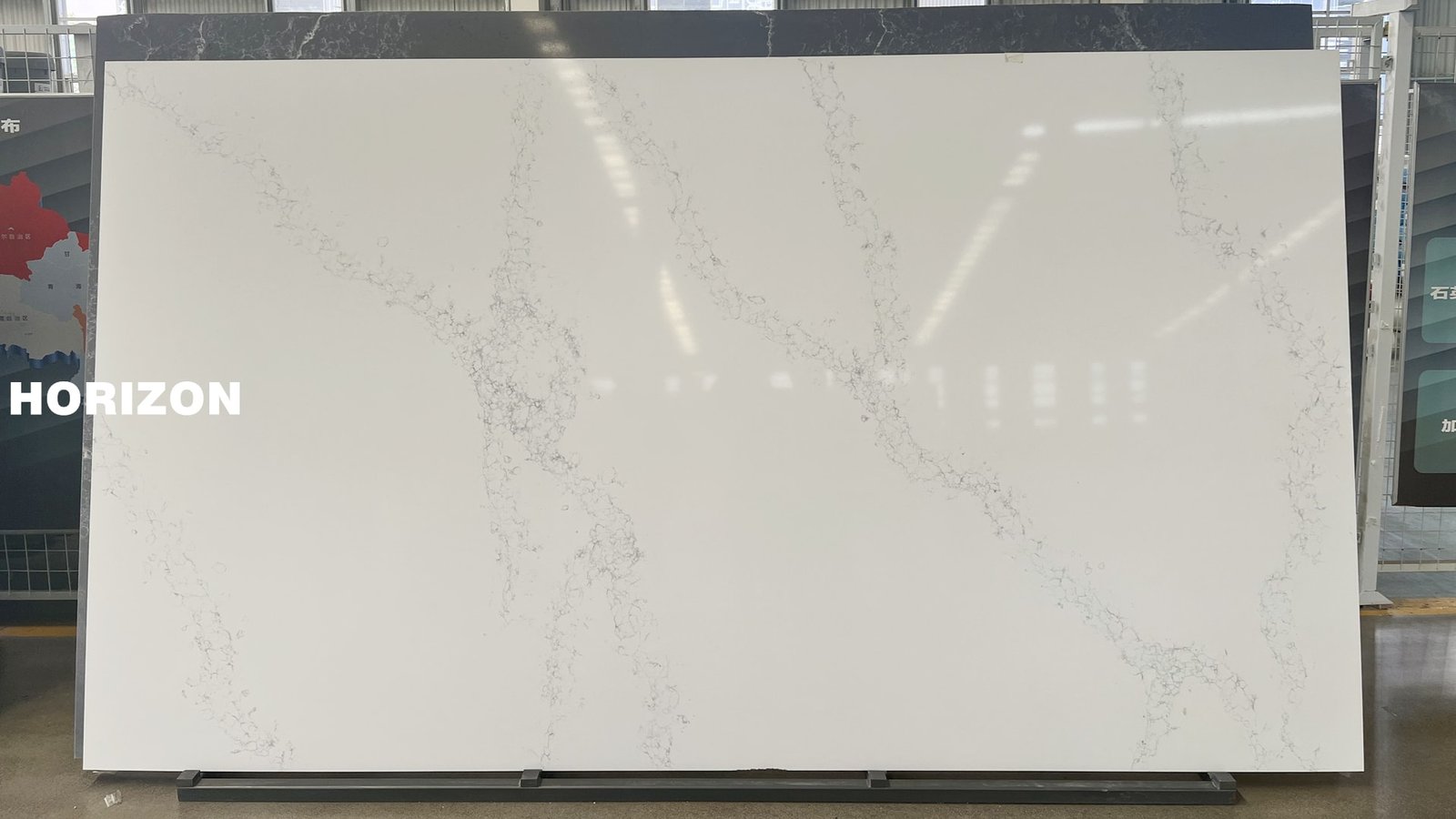

Quartz Calacatta AU001

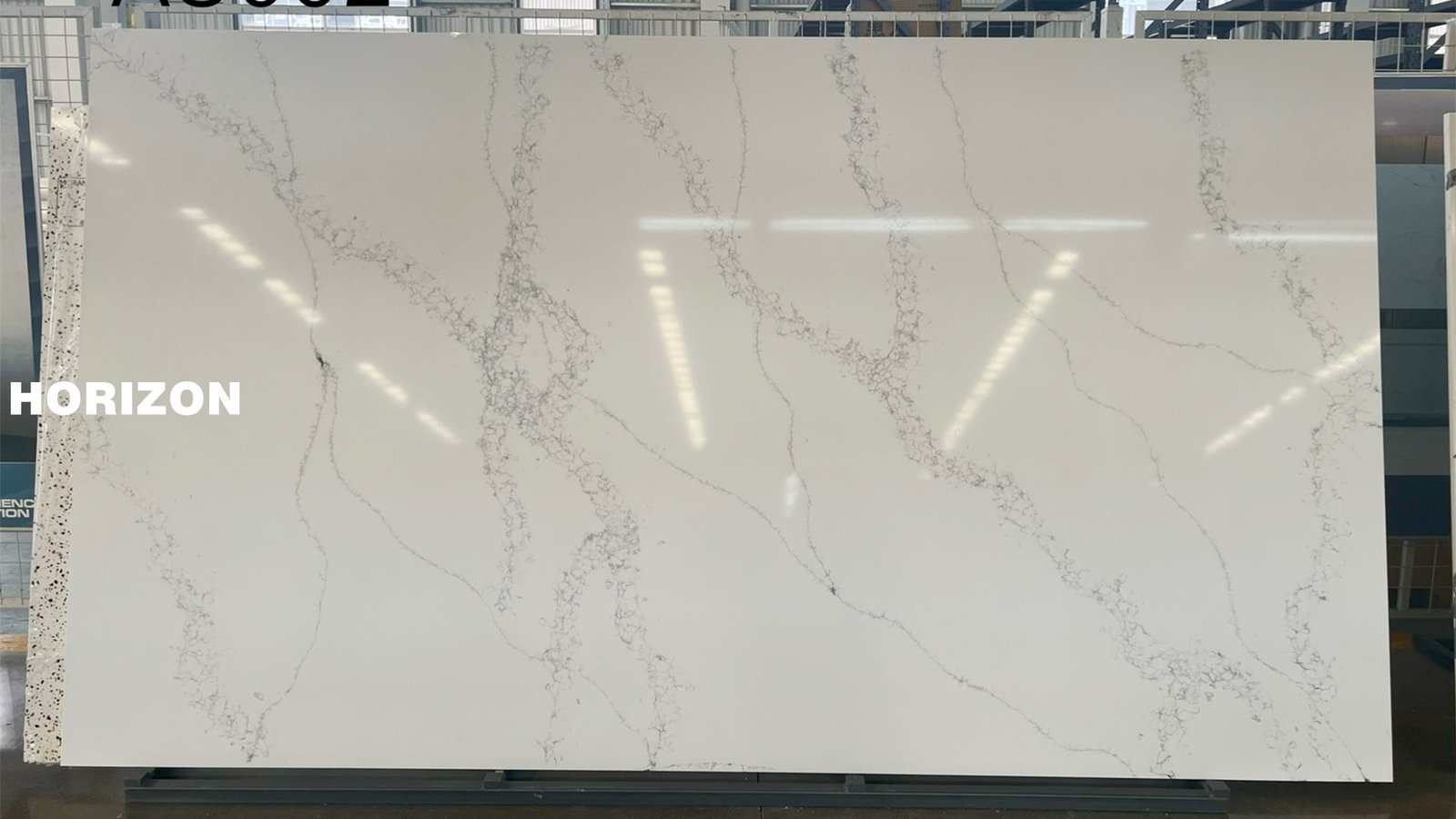

Quartz Calacatta AU002

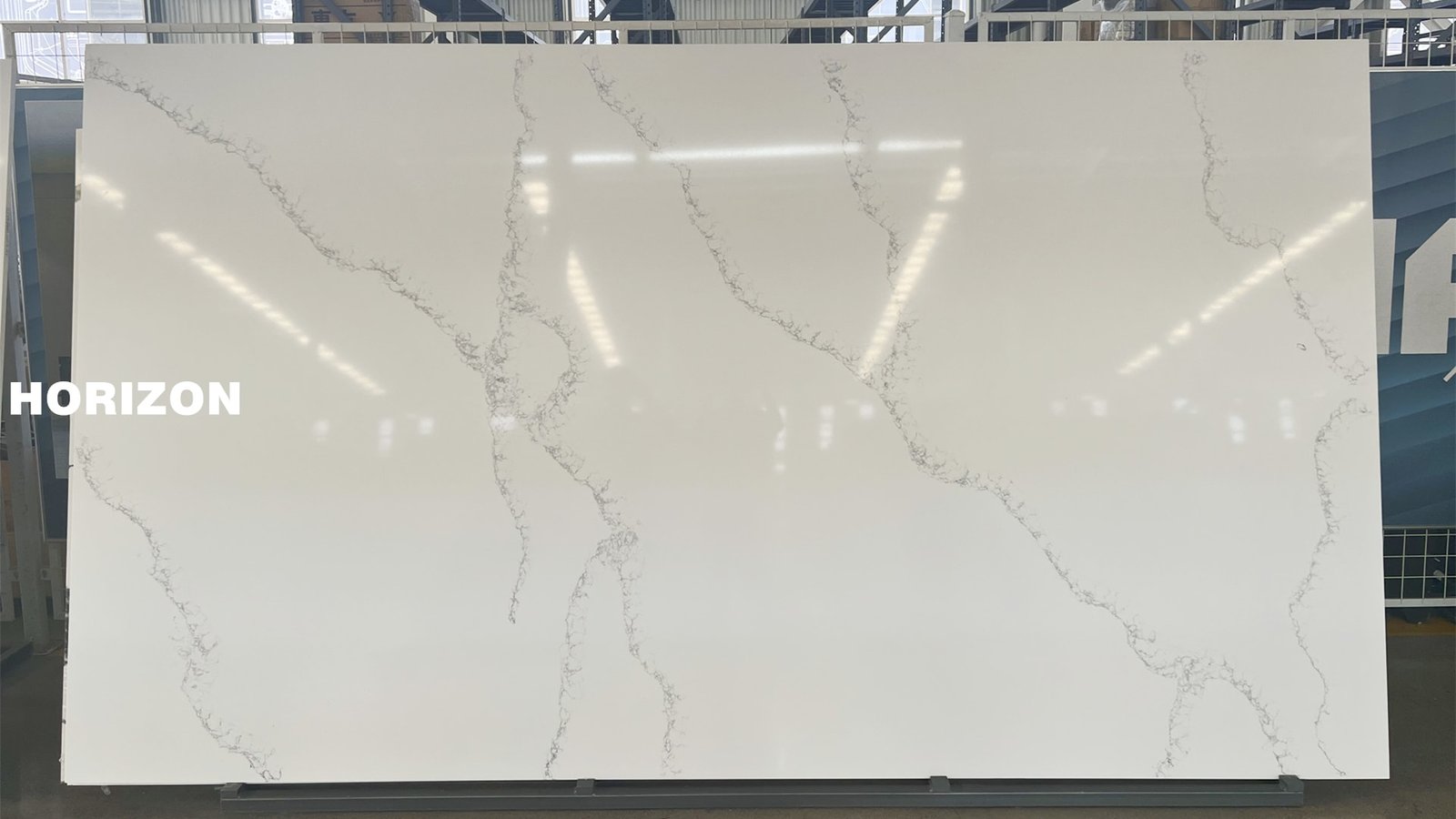

Quartz Calacatta AU003

Great Companies Are Built On Great Products. – Tesla Motors CEO Elon Musk

Related Links

Horizon YouTube Channel: HORIZON GROUP – Top Quartz Stone Slabs Manufacturer

Gallery: Horizon Quartz Calacatta

Request To Get Best Price: Whatsapp +86 150 5425 3293

Best: Horizon Best Angle

Great article! I really appreciate the clear and detailed insights you’ve provided on this topic. It’s always refreshing to read content that breaks things down so well, making it easy for readers to grasp even complex ideas. I also found the practical tips you’ve shared to be very helpful. Looking forward to more informative posts like this! Keep up the good work!